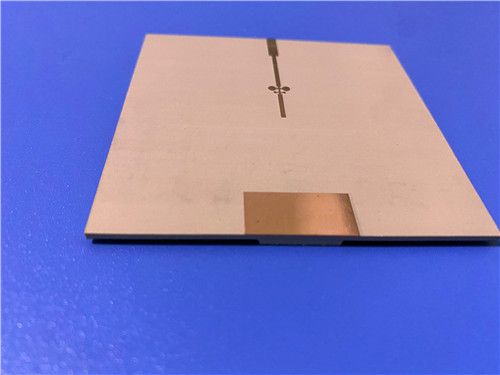

IsoClad 933 2-Layer High-Frequency PCB for RF and Military Electronics

1.Introduction

IsoClad 933is a premium PTFE-based laminate designed for high-frequency printed circuit boards. This 2-layer PCB material combines nonwoven fiberglass reinforcement with PTFE's exceptional electrical properties, offering outstanding signal integrity for RF, microwave, and defense electronics.

2.Key Features

Low Dielectric Constant: 2.33 at 10GHz for minimal signal loss

Ultra-Low Dissipation: 0.0016 loss tangent at high frequencies

Thermal Stability: -132 ppm/°C thermal coefficient of dielectric constant

Mechanical Strength: 10 lbs/inch peel strength for durability

High Voltage Resistance: >45 kV dielectric breakdown

Flame Retardant: UL94 V-0 certification

3.PCB Construction Specifications

| Parameter | Specification |

|---|---|

| Base Material | IsoClad 933 |

| Layers | 2 |

| Board Size | 50mm × 60mm (±0.15mm) |

| Trace/Space | 4/4 mils |

| Min Hole Size | 0.25mm |

| Board Thickness | 0.8mm |

| Copper Weight | 1oz (outer layers) |

| Via Plating | 20 μm |

| Surface Finish | ENIG |

| Silkscreen | None (Top/Bottom) |

| Solder Mask | None (Top/Bottom) |

| Electrical Test | 100% tested |

4.PCB Stackup:

Copper layer 1 - 35 μm

IsoClad 933 Core - 31mil (0.787 mm)

Copper layer 2 - 35 μm

5.Board Statistics

Components: 16

Total Pads: 35

Thru Hole Pads: 21

Top SMT Pads: 14

Bottom SMT Pads: 0

Vias: 16

Nets: 2

6.Manufacturing & Quality Standards

Artwork Format: Gerber RS-274-X

Quality Standard: IPC-Class 2

Availability: Worldwide shipping

7.Technical Advantages

Less rigid than woven fiberglass, suitable for flexible applications.

Highly isotropic in X, Y, and Z directions for consistent performance.

8.Target Applications

Conformal antennas

Stripline and microstrip circuits

Missile guidance systems

Radar and electronic warfare systems